From chaos to organisation

Many projects develop into ailing project over the course of their lifespan because one or more of the project targets – costs, deadlines or quality – have not been achieved or can no longer be achieved. This trend can be applied to the whole construction industry, not just individual parts of it such as structural engineering. According to a study by the Hertie School of Governance in 2015, the above-mentioned failings in major public projects in Germany result in an average cost overrun of up to 44 per cent.

The causes can be very diverse and range from unrealistic targets, changing targets during the project to breaches of responsibility on the part of those involved in the project (client, planner and contractor) and often in combination with each other. If countermeasures can successfully be implemented in the ongoing project, missed project targets can be minimised and this the damage reduced. This is where crisis management comes in. Frequently a project goal has been missed before the project managers recognise the need for crisis management and implement it. The core of crisis management is therefore damage limitation, because the deadline has already been missed or costs already exceeded.

Six Sigma in Crisis management

Six Sigma is a management system which improves processes and results by building on existing processes. Based on the Six Sigma system, THOST has developed a methodology which brings projects that have got into difficulties to a scheduled and successful conclusion.

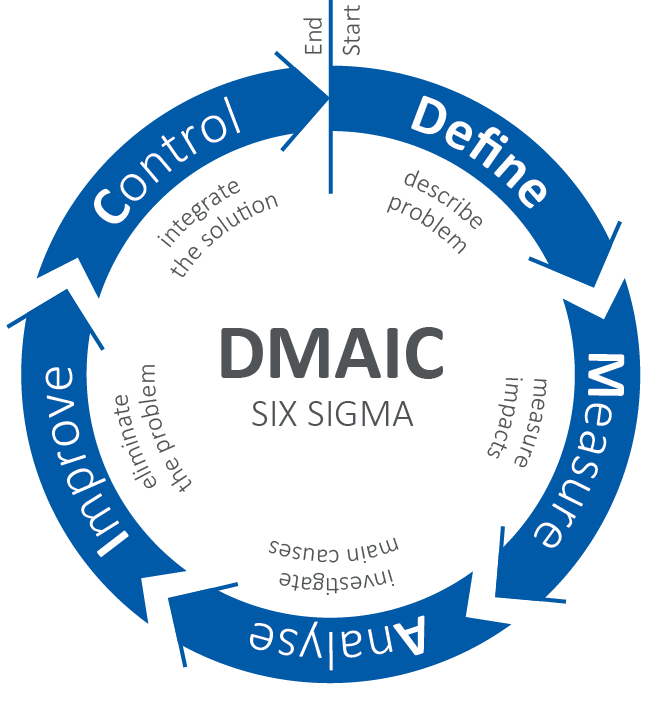

The core of Six Sigma is the DMAIC process. This is a 5 stage process containing the following stages:

The 5-step process starts with step 1 "Define". The aim of this stage is to clarify what kind of problem is involved. Customer requirements are to be identified. The process is to be described and the financial and scheduling implications are to be estimated.

In stage 2 "Measure", data collection is carried out. The aim of this stage is to clarify the scope of the problem. This involves determining and selecting measurement variables, checking the measurement system and presenting measured data.

"Analysis" is stage 3 of the process. Here the main causes of the problem are to be clarified. The processes affecting the problem must be analysed in detail and the causes and main effects of the problem identified.

Stage 4 "Improve" is the development of the problem solution. Creative solutions are to be developed on the basis of the preceding process steps and evaluated in the context of alternative solutions. Finally, a solution approach is to be selected and implemented.

In stage 5 "Control", the sustainability of the improvement or problem solution must be ensured. Here the quality of the new process has to be checked. Changes are to be documented and standardised. The know-how of the improvement process has to be worked out and transferred within the team.

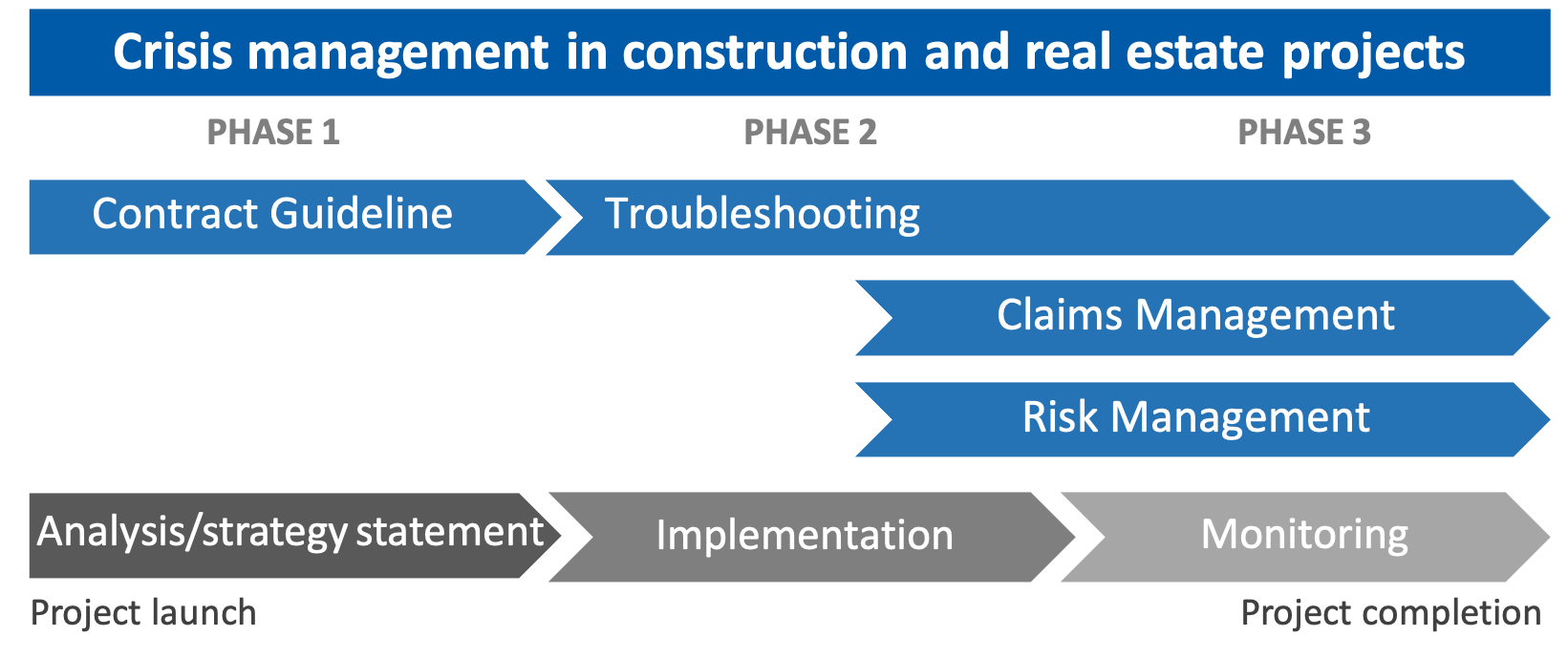

Krisenmanagement in construction and real estate projects

- Describing the problem

- Identification and analysis of potential optimisation

- Contracts analysis

- Identify communication conflict

- Schedule and delay analysis

- Analysis of existing processes and project structure

- Evaluation, recommendations for action and strategy

- Assistance with the consolidation of contracts

- Assistance with the consolidation of project structure and project processes

- Conflict resolution

- Option: Construction management

- Risk management

- Reporting

- Project controlling

- Construction management

- Option: Lean management in construction

- Conflict resolution

- Risk management

- Reporting